Nine years before Neil Armstrong (Astronaut) set foot on the base of the moon, Swiss oceanographer Piccard and US Navy Lieutenant Walsh climbed aboard the bathyscaphe Trieste for a harmful, unexpected expedition to the base of the Mariana Trench – the deepest recognize place of all the world’s oceans more than 35k feet below the surface of the Pacific.

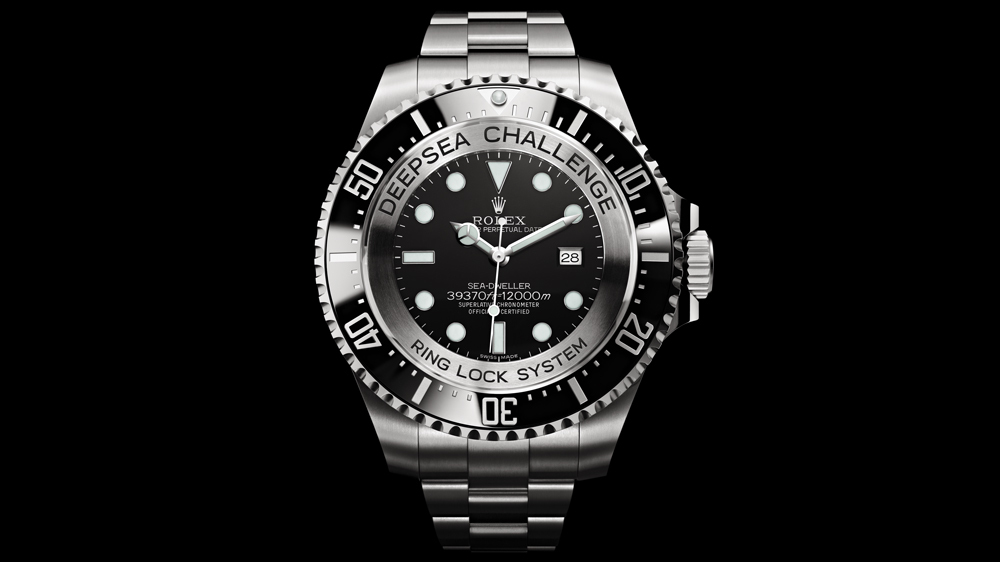

They did so with an experimental Rolex deep seal special wrist timepiece connected to the exterior of the submersible. Upon their return to the base, as famous in watch lore, Piccard sent Rolex headquarters a Telegram that stated, very Happy to announce your timepiece as precise at 11k meters down as on base.

They did so with an experimental Rolex deep seal special wrist timepiece connected to the exterior of the submersible. Upon their return to the base, as famous in watch lore, Piccard sent Rolex headquarters a Telegram that stated, very Happy to announce your timepiece as precise at 11k meters down as on base.

The pairing of these two items, submersible items, timepiece, and submarine mirror a parallel set of technological challenges and refinements which continue to this time. One of the clearest of those challenges is accounting for the managing dynamics for a pressure hull, which applies to both the watch and the submarine.

The pairing of these two items, submersible items, timepiece, and submarine mirror a parallel set of technological challenges and refinements which continue to this time. One of the clearest of those challenges is accounting for the managing dynamics for a pressure hull, which applies to both the watch and the submarine.

As the submarine starts to dive, it gets squeezed jointly and into shape, said principle design engineer John Ramsay at Triton Submarines, when you start getting deeper, the sub starts to steal itself. Just because of that, the strength and the shape of a submersible are the most vital aspects of its construction.

As the submarine starts to dive, it gets squeezed jointly and into shape, said principle design engineer John Ramsay at Triton Submarines, when you start getting deeper, the sub starts to steal itself. Just because of that, the strength and the shape of a submersible are the most vital aspects of its construction.

The real challenge that watch manufacturers and submarine engineers have in common is from, says President of SEAMAGINE Hydrospace Corporation, Charles Kohnen, a developer of personal Submersibles, the style of the pressure vessel is just as vital – if not more vital than the content. How uniformly is the force allocated around the shape that is an extremely vital aspect?

The real challenge that watch manufacturers and submarine engineers have in common is from, says President of SEAMAGINE Hydrospace Corporation, Charles Kohnen, a developer of personal Submersibles, the style of the pressure vessel is just as vital – if not more vital than the content. How uniformly is the force allocated around the shape that is an extremely vital aspect?

That being stated, the base O Ring seal is the main design feature for watertight feature for both of these items, expertise rubber for O rings, like VITON, EPDM (NITRILE and Ethylene Propylene DIENE) have also modern waterproofing abilities, since they can withstand very deeper and cold temperatures much better than usual rubber.

That being stated, the base O Ring seal is the main design feature for watertight feature for both of these items, expertise rubber for O rings, like VITON, EPDM (NITRILE and Ethylene Propylene DIENE) have also modern waterproofing abilities, since they can withstand very deeper and cold temperatures much better than usual rubber.